Water-Based Suppression Systems

Include water mist systems which produce ultra-fine water droplets to safely protect electronic and other high-value applications, and water cannons which are ideal for more spacious environments.

DuraQuench® Pro

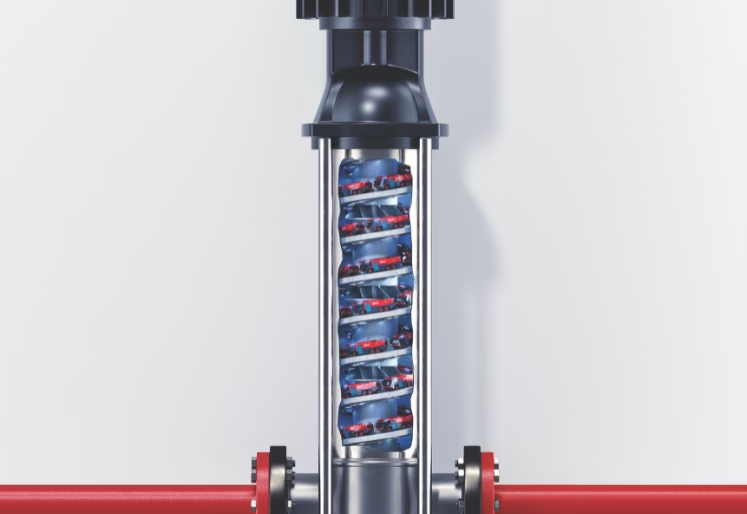

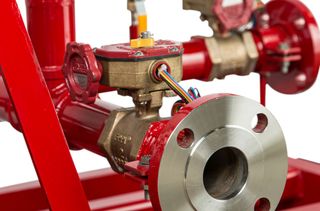

Pumped Water Mist System

Connects to the facility’s water main or local reservoir to provide unlimited discharge of low-pressure water mist suppression via a skid-mounted centrifugal pump. The FM-approved system operates at just 175 psi rather than the 1000-2000 psi on average of high-pressure systems, resulting in lower total cost of ownership.

DuraQuench Features:

- Small Footprint, Large Coverage

-

Just one unit may protect multiple zones, creating endless possibilities for system design and configuration.

- Ease Of Implementation

-

A low-pressure system allows for maximum flexibility of pipe options, including copper, stainless steel and CPVC light hazard applications, which can all be sourced from your preferred local supplier.

- Corrosion Resistant

-

Only pipe system components and fittings which are resistant to metal oxidation and MIC (microbiologically influenced corrosion), such as stainless steel, copper and CPVC, are used on the system.

- Avoid New Construction

-

May be used when sprinkler systems require installing a new water tank, upgrading the water supply line, and other scenarios when water supplies are limited.

Fike DuraQuench FM-Approved Applications

Data centers

Uses closed-head pre-action system nozzles for server rooms, including upright nozzles for subfloors. Possesses FM approvals for data processing rooms (both above and below floor) and for local application design.

Turbines (Steam and Diesel)

Deluge system with open nozzles fills the space with water mist, suppressing fires on the pump, bearings and shaft as well as extinguishing lube fires. Ideal replacement for CO2 suppression.

Machinery Enclosures

For spaces containing internal combustion engines, oil pumps, oil tanks, fuel filters, generators and more, a deluge system with open nozzles is recommended. Ideal replacement for CO2 suppression.

Light Hazard

A wet alarm system using closed-head nozzles and water-filled pipes is recommended for apartments, hospitals, hotels, churches, libraries, restaurants, schools and more.

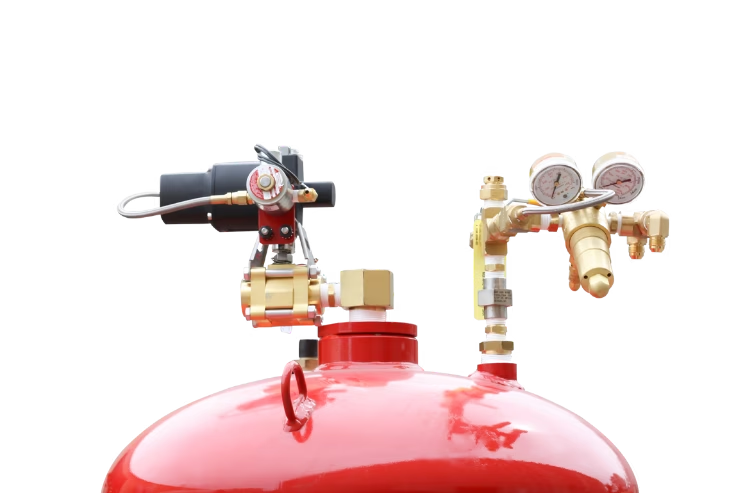

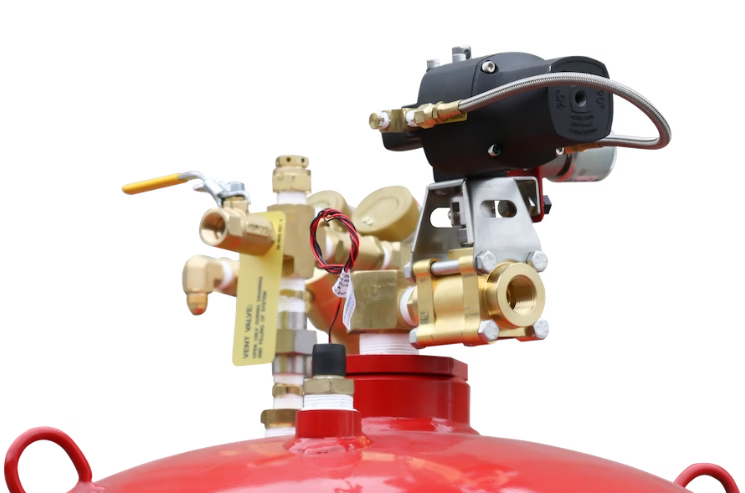

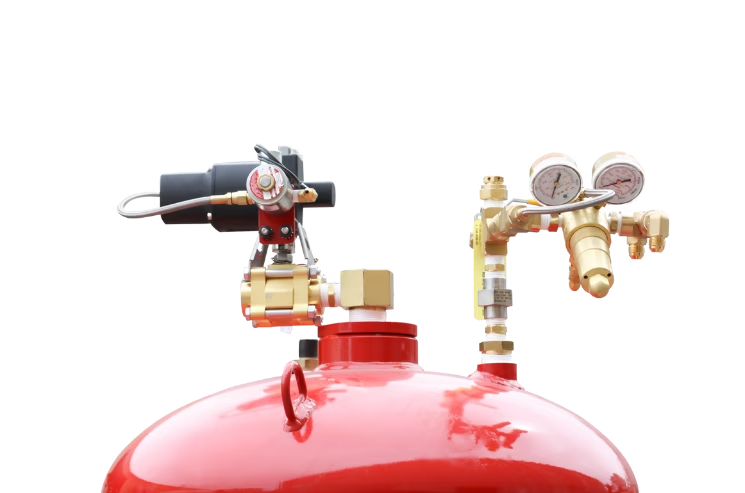

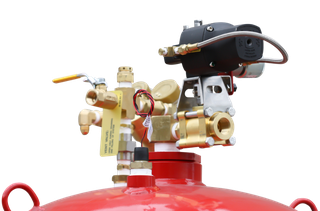

Fike Micromist®

Self-Contained Water Mist System

Comes pre-assembled and packaged with all necessary valves and actuation components* to offer a relatively simple-to-install yet effective water mist solution for applications where Fike DuraQuench isn’t possible.

Micromist Features:

- Remote Locations

-

Ideal for applications without an available water source, and may protect areas up to 9175 ft3 with a maximum ceiling height of 16 ft.

- Class B Fire Protection

-

Uses a brass nozzle which has been proven to extinguish flammable liquid (Class B) fire scenarios as well as spray fires which could ignite from a ruptured hose or pipe in a process using flammable liquids.

- Flexible Options

-

Offered in 70 and 112 gallon configurations, allowing flexibility when choosing the necessary amount of water suppression for the protected space.

Fike Fire Monitors

Offers automatic and precise fire suppression for hard-to-reach fires, often within just 15 seconds of detection. May be paired with any of Fike fire detection systems to create the ultimate water-based fire suppression solution.

- Reliable Suppression

-

Discharges up to 1,320 gallons per minute up to 87 yards away in a total nozzle spray pattern.

- Manual & Remote Access

-

A human operator may also operate the robotic nozzle remotely by means of a joystick, wireless radio, iOS or Android app or computer anywhere in the world.

- Variety of Applications

-

Suitable for waste and recycling facilities, industrial and manufacturing buildings, outdoor storage facilities, marine applications, aircraft hangars and more.

Variety of Applications

Aircraft Hangars

Marine Applications

Waste & Recycling Management

Coal Storage

How does a deluge pumped water mist system (Fike DuraQuench) work?

1. Water Readied

In a dry pipe network, the water supply is held back by a deluge valve. In a wet pipe network, the water is held back by an OH-VSO nozzle.

2. Dry Pipe Activation

In a dry pipe network, when a fire condition is detected a deluge valve is opened and the fire pump is activated sending pressurized water throught he network and into the open K6 nozzles.

3. Wet Pipe Activation

In a wet pipe network, the bulb in the OH-VSO nozzles will break, the water flow switch paddle will move and go into alarm. The signal will go to the releasing panel and then to the fire pump controller to activate the fire pump.

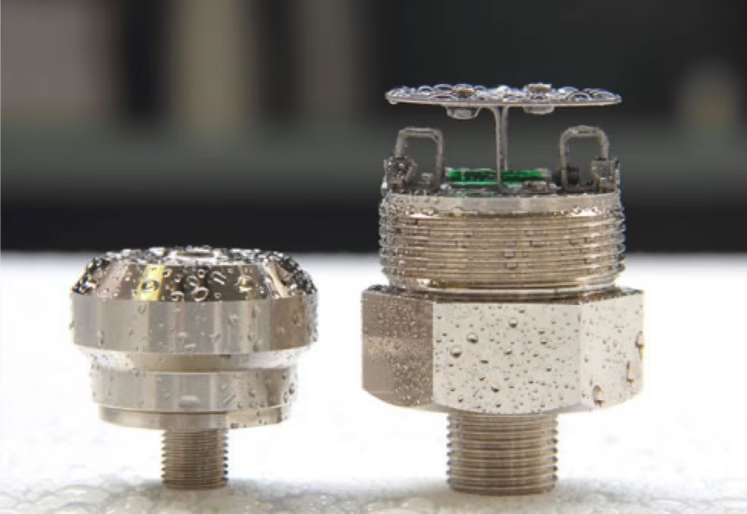

4. Nozzles Create Mist

Nozzle design shears the water into small droplets, which are effective at producing water vapor when they make contact with the fire.

What are the benefits of water mist versus water sprinklers?

Critical Asset Protection

Sprinklers are intended to protect occupants and the building itself until fire personnel arrive. Conversely, water mist systems are considered “special hazard fire protection” because they are engineered to quickly extinguish the fire and protect high-value assets such as servers, computers, files, art, historical or cultural artifacts, and of course the building itself.

Penetration Of Obscured Fires

A fire occurring at the bottom of a trash pile, under a desk or within a server cannot be reached by the large water droplets from a conventional sprinkler system. Water mist systems offer “3D” coverage, meaning the ultra-fine water droplets have the ability to penetrate and suppress these obstructed fires.

No Collateral Damage

It’s no secret that a sprinkler system activation can create problems itself, often resulting in damage to electronics, furniture and flooring, and in hours of cleanup. Water mist uses a fraction of the water used by conventional sprinkler systems, resulting in very little to zero damage and cleanup after activation.

How does a self-contained water mist system work?

1. Fire Detected

When a fire condition is detected in the protected hazard, a releasing fire control panel sends a signal to the releasing module to operate the self-contained water mist suppression system (Micromist).

4. Nozzles Create Mist

Nozzle design shears the water into small droplets, which are effective at producing water vapor when they make contact with the fire.

2. Air Pressure Flows

Valves on the nitrogen tanks open and the resulting air pressure flows through a pressure regulating valve (PRV) which regulates the pressure and drives the water through the opened water valve and to the system nozzles.

5. Fire Extinguished

The water droplets absorb heat, oxygen is displaced by steam generation, and the cooling effect washes out combustion products, resulting in reliable fire extinguishment.

3. Water Discharges

The Micromist system uses relatively short pulses of water to aid in the extinguishment of fires as well as minimize the property damage associated with a continuous discharge.

How does NFPA define the various types of water mist systems?

According to NFPA 750 7.2, water mist systems can be categorized into:

Local-Application Systems are designed and installed to provide complete distribution of mist on or around the hazard or object to be protected.

Total Compartment Application Systems are designed and installed to provide complete protection of an enclosure or space

Zoned Application Systems are designed to protect a predetermined portion of the compartment by the activation of a selected group of nozzles.

Occupancy Protection Systems are designed and installed to provide automatic fire protection throughout a building or occupancy.

What types of fires does water mist protect against?

According to NFPA 750 A.3.3.24, “Properly designed water mist systems can be effective on both liquid fuel (Class B) and solid fuel (Class A) fires. Research indicates that fine (i.e., smaller than 400 microns) droplets are essential for extinguishment of Class B fires, although larger drop sizes are effective for Class A combustibles, which benefit from extinguishment by fuel wetting.”

Which industries and applications are water mist suppression systems effective at protecting?

According to NFPA 750 A.4.1, “Water mist systems have proved effective in controlling, suppressing, or extinguishing many types of fires...including: gas jet fires, flammable and combustible liquids, hazardous solids...

Class A combustible fires such as paper, wood and textiles; electrical hazards, such as transformers, switches, circuit breakers rotating equipment and cable tunnels; electronic equipment, including telecommunications equipment; highway and railway tunnels; fighter aircraft hangers, light aircraft hangers, and helicopter hangers.”

Are there any materials not to protect with water mist?

According to NFPA 750 4.1.1.2, “Water mist systems shall not be used for direct application to materials that react with water to produce violent reactions or significant amounts of hazardous products. Such materials include the following: reactive metals, such as lithium, sodium, potassium, magnesium…metal alkoxides; metal amides; carbides; halides, etc.”